ST1100 Dash ShelfItems Needed:• Aluminum sheet metal at least 2mm thick and checkerboard pattern

• Angle grinder

• Straight file

• Different grades of sandpaper

• Rubber mallet

• Hacksaw blade

• Drill and 2 & 5mm drill bits

• Scribe or sharp nail

• Paint – metal primer and topcoat (recommend matt black)

• Vice

• 1hr not including paint drying time

• Small washers – Optional (6)

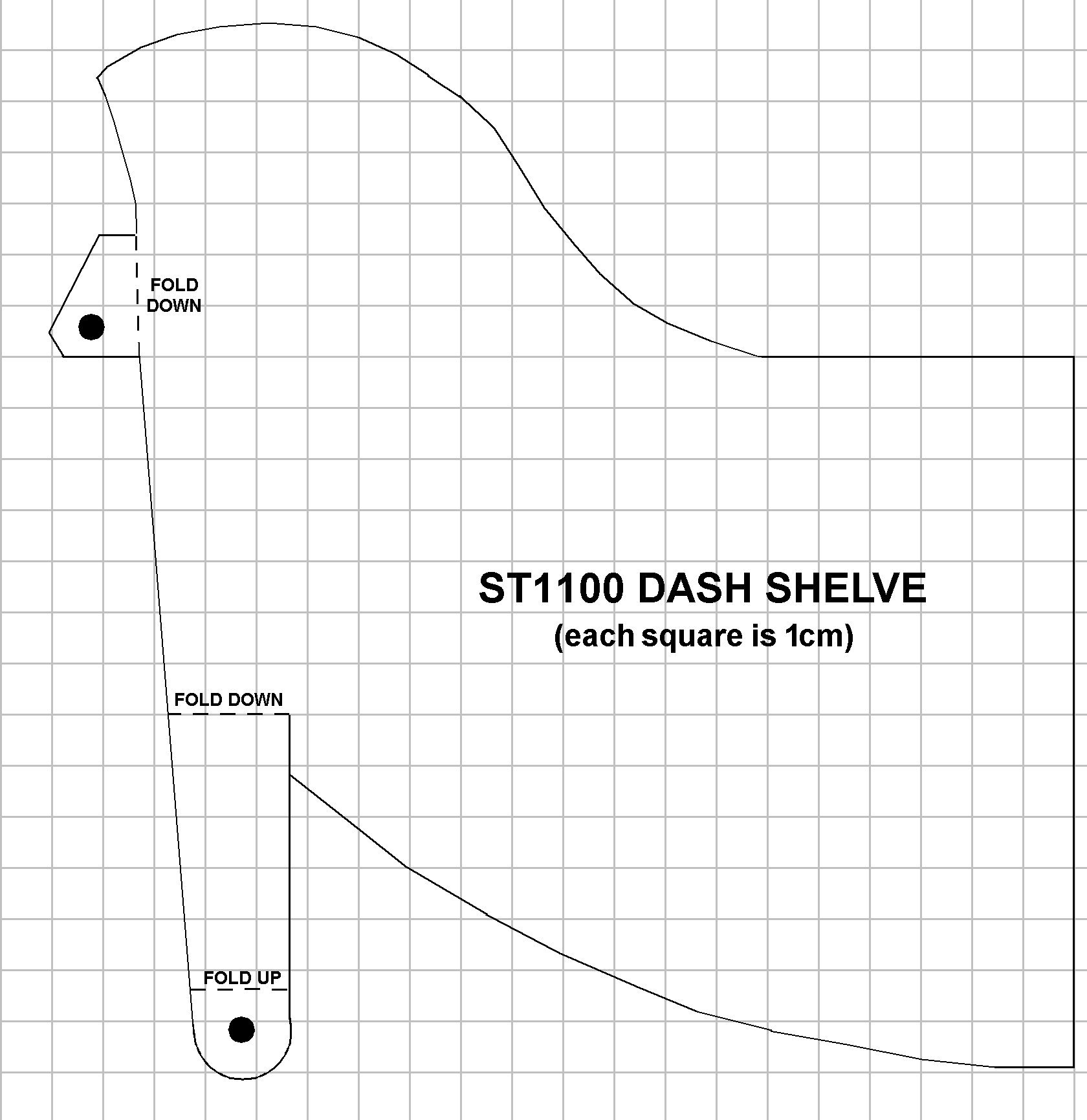

Note: the shape of this shelf (my own design) maximises available space without restricting your view of the warning lights.

I recently bought a new GPS (A TomTom Rider) to replace the ALDI one I had had for the last 4 years (A Go-Cruise) Great GPS – much maligned.

My original dash shelf was made of light weight metal and as a result the TomTom bounced around quite a lot.

First off I made a new mounting bracket instead of using the ram mount that came with the TomTom (as it was quite high) but the bounce continued. My plan was therefore to remove the bounce from the dash shelf by making a second shelf this time out of a much thicker material.

So off to Bunnings and I picked up a 2mm Checkerboard Aluminum sheet for $34.00.

My original 1mm shelf I was able to cutout with tin snips but this one was a little harder so I decided on the angle grinder. I removed my windscreen and then the existing shelf, bashed it with a rubber hammer (until it was quite dead and flat) and made up a template which needs to be mirrored.

After tracing the image on the back of the metal sheet I cut out the shape with the grinder. There was plenty of sheet left over for the next project.

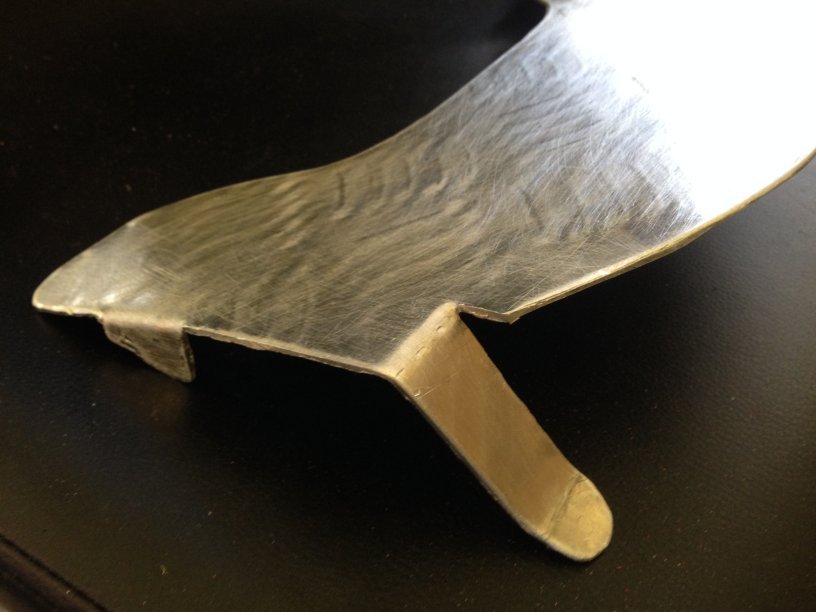

However as you can see the grinder leave a fairly rough edge

So the first order of business is to remove all the rough edges with a file then sandpaper. Don’t be tempted to use a mechanical sanding device as it will damage the edges.

Finally sand the entire underside of the plate (which is actually the top of the shelf) as this creates a nice rough surface for the paint to bond to. Also using a hacksaw blade tidy up the cuts next to the front legs.

Place the shelve in the vice and using a rubber mallet bend the legs and side tabs accordingly. (I always bend these the wrong way initially so think about the direction they need to go in)

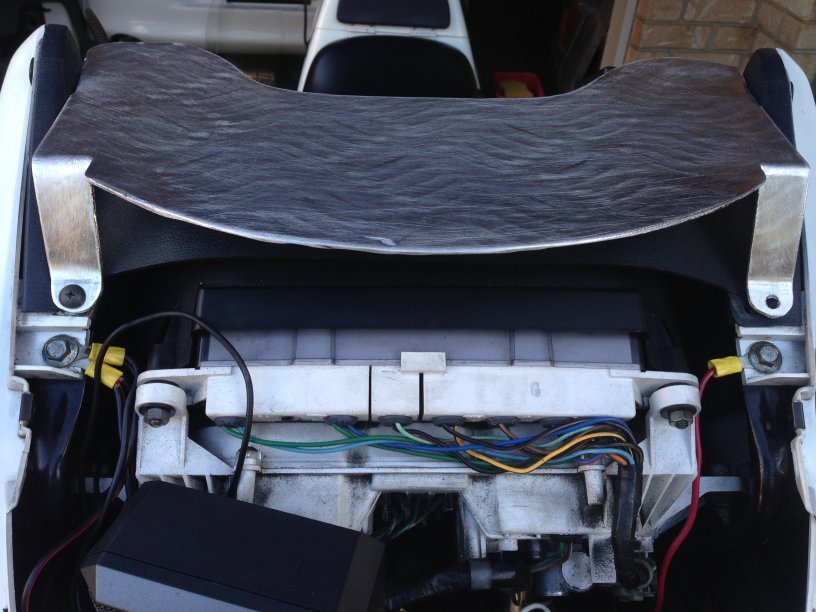

Now drill the holes with a 2mm drill and then the 5mm. The holes need to be reasonably close to the edge as below.

With this done, you are ready for a test fit. I will guarantee that the holes will not align 100%.

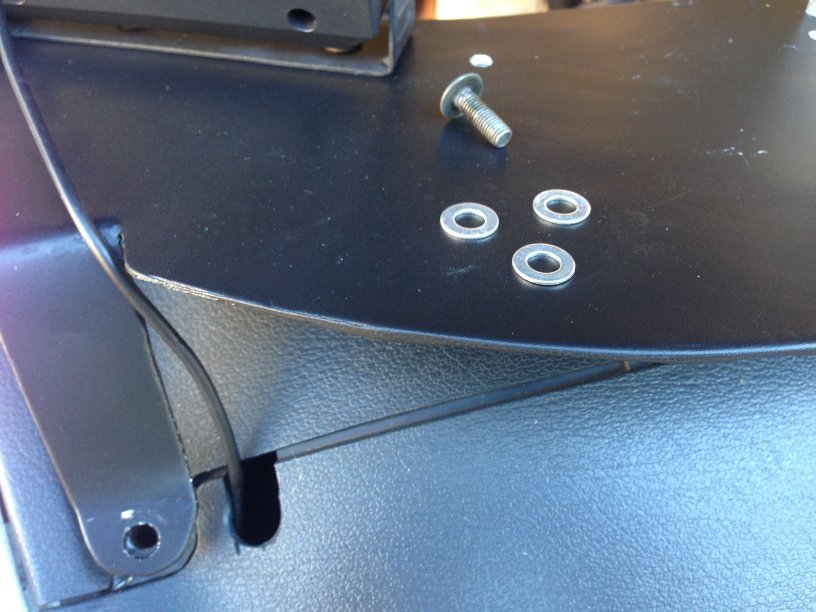

However, the fact that we have made this out of aluminum means that the legs can be adjusted to fit perfectly. (Hint – always fit the side tabs first and never tighten any bolt up until all are in place)

Time for a final sand, clean and spray with a suitable primer for aluminum. (Hint – If you are going to mount accessories on the shelf [isn’t that what it’s for] and you know exactly where they are going, then drill the holes now).

I use dry gal as my primer for everything and it works fine.

After a suitable drying time (1hr for the Gal) spray the top coat or two.

Nearly there….. One final tip the front legs will be sitting on plastic that is not completely flat. If you are anal like me about your bike, you may want the stick three small washers together to place them between the leg and the plastic, this will prevent the plastic cracking over time – trust me)

Fit and farklise…

Regards,

Adrian